CO2 Cannabis Extraction Machines: Enhancing Efficiency and Protecting Plants

Realizing CO2 Cannabis Extraction

Basic Principles of CO2 Extraction

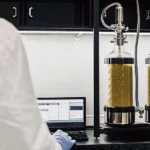

CO2 cannabis extraction machines have revolutionized the cannabis industry by providing an efficient and clean method to extract cannabinoids and terpenes from cannabis plants. The basic principle involves using supercritical CO2 as a solvent to separate the desired compounds from the plant material. Unlike other solvents, CO2 is non-toxic and non-flammable, making it an environmentally friendly option for cannabis extraction.

The process begins by subjecting CO2 to high pressure and low temperature, turning it into a supercritical fluid. In this state, CO2 exhibits properties of both a liquid and a gas, allowing it to permeate the plant material and dissolve cannabinoids and terpenes effectively. Once the CO2 has absorbed the compounds, it’s depressurized, allowing it to return to its gaseous state and leaving behind a pure, concentrated extract. This method ensures that the final product is free from residual solvents and contaminants, aligning with the industry’s shift towards clean and sustainable cannabis production.

Recommended Strains

Black Domina

|

|

THC | 15% - 20% (Medium) |

|

|

Type | Feminized |

|

|

Yield | High |

|

|

Phenotype | 95% Indica / 5% Sativa |

Black Domina Auto

|

|

THC | 10% - 15% (Low) |

|

|

Type | Autoflowering |

|

|

Yield | Low |

|

|

Phenotype | 85% Indica / 15% Sativa |

Advantages of Using CO2

The use of CO2 in cannabis extraction offers several key advantages over traditional methods. Firstly, CO2 is a highly tunable solvent, allowing operators to adjust pressure and temperature to target specific compounds. This level of control enables the production of full-spectrum extracts, preserving the plant’s natural profile and enhancing the entourage effect. Furthermore, CO2 extraction is a closed-loop system, minimizing the risk of contamination and ensuring the safety of both operators and consumers.

Another significant benefit is the environmental impact. CO2 is a naturally occurring compound that can be recycled within the extraction system, reducing waste and lowering operational costs. Additionally, CO2 extraction machines produce extracts with higher purity and potency, optimizing the yield from each batch of cannabis. These factors combined make CO2 cannabis extraction machines an attractive option for businesses aiming to produce high-quality, consistent products while adhering to environmental and safety standards.

Promos & Deals

Key Components of the CO2 Cannabis Extraction Machine

Main Parts and Their Functions

To fully appreciate the capabilities of a CO2 cannabis extraction machine, it’s essential to understand its main components and their functions. The machine consists of several key parts, each playing a crucial role in the extraction process. The extractor vessel holds the raw cannabis material and is designed to withstand high pressures, ensuring the efficient transfer of cannabinoids and terpenes into the CO2 stream.

Another vital component is the separator, where the extracted compounds are isolated from the CO2. The separator allows for precise control over pressure and temperature, facilitating the collection of specific cannabinoids and terpenes. Additionally, the CO2 pump maintains the necessary pressure to keep the CO2 in its supercritical state, while the heat exchanger ensures optimal temperature regulation throughout the process. These components work in harmony to maximize extraction efficiency and quality.

Technical Specifications

When evaluating a CO2 cannabis extraction machine, knowing its technical specifications is paramount. These machines vary in size, pressure capacity, and throughput, affecting their suitability for different production scales. Typically, machines are rated by their pressure capacity, measured in pounds per square inch (PSI), and their flow rate, determining how much plant material can be processed per cycle.

Advanced CO2 extraction machines are equipped with automated controls, enabling precise adjustments to pressure and temperature settings. This feature enhances the reproducibility of the extraction process, ensuring consistent product quality. Moreover, some machines offer modular designs, allowing for scalability as production demands increase. By considering these technical aspects, operators can select a CO2 extraction machine that aligns with their specific needs and operational goals.

Operational Guidelines for CO2 Cannabis Extraction Machines

Safe Operating Procedures

Ensuring the safe operation of CO2 cannabis extraction machines is a top priority for any extraction facility. Operators must be well-trained in the specific procedures and safety protocols associated with these machines. A comprehensive understanding of the machine’s pressure and temperature settings is essential to prevent accidents and equipment damage. Additionally, regular maintenance checks are vital to identify any wear and tear on critical components, such as gaskets and seals.

Implementing strict safety measures, such as routine inspections and emergency shut-off procedures, can mitigate potential hazards. It’s also crucial to maintain a clean and organized workspace, free from any flammable materials or obstructions. By adhering to these guidelines, operators can ensure a safe and efficient extraction environment, safeguarding both personnel and product integrity.

Maintenance and Troubleshooting

Proper maintenance is fundamental to the longevity and optimal performance of a CO2 cannabis extraction machine. Regular inspections of the machine’s components, such as pumps, valves, and seals, can prevent unexpected breakdowns and costly repairs. Operators should follow the manufacturer’s recommended maintenance schedule, which typically includes tasks like lubricating moving parts and replacing worn-out components.

In the event of operational issues, troubleshooting steps can help identify and resolve problems quickly. Common issues include pressure fluctuations, temperature inconsistencies, and clogged filters. By documenting these occurrences and their resolutions, operators can create a knowledge base to address future issues effectively. Maintaining open communication with the machine’s manufacturer or a qualified technician can also provide valuable support in troubleshooting complex problems.

Efficiency and Yield Considerations in CO2 Cannabis Extraction

Maximizing Extraction Efficiency

Achieving maximum efficiency in CO2 cannabis extraction is crucial for optimizing product yield and reducing operational costs. One strategy to enhance efficiency is to finely tune the machine’s pressure and temperature settings to target specific cannabinoids and terpenes. This precision allows operators to extract the desired compounds more effectively, minimizing waste and maximizing the use of raw materials.

Moreover, implementing a consistent pre-processing routine, such as grinding and drying the cannabis material, can improve the extraction process. Uniform particle size and moisture content ensure even exposure to the CO2 solvent, resulting in a more thorough extraction. By continuously monitoring and adjusting these parameters, operators can achieve higher extraction yields and produce superior quality extracts.

Quality of the Final Extract

The quality of the final extract is a critical consideration for any cannabis producer. CO2 cannabis extraction machines are renowned for producing high-purity extracts, free from residual solvents and contaminants. To maintain this standard, operators must prioritize quality control measures throughout the extraction process. Regular testing of the raw material and final product can help identify any potential issues, such as pesticide residues or microbial contamination.

Additionally, maintaining optimal machine conditions, such as pressure and temperature, contributes to the production of consistent and high-quality extracts. The ability to produce full-spectrum extracts, rich in cannabinoids and terpenes, sets CO2 extraction apart from other methods. By focusing on quality control and process optimization, producers can deliver premium cannabis products that meet consumer demands and regulatory standards.

Why Choosing the Best Seeds Matters for Cannabis Extraction

When it comes to cannabis extraction, starting with the right genetics is everything. High-quality extractions depend on strains that deliver exceptional resin production, rich terpene profiles, and potent cannabinoid content. Not all seeds are created equal some strains were bred specifically for flavor, others for yield, and only a select few bring the resin-loaded traits needed for top-shelf concentrates. Whether you’re making rosin, BHO, or live resin, the best seeds will give you the sticky, aromatic, and trichome-dense flowers that result in superior extracts. For hash makers and extract artists, choosing proven extraction-grade genetics is the first step to creating clean, flavorful, and powerful results.

OG 18 Kush Cannabis Extraction

OG 18 Kush Cannabis extraction is a legend among extractors for a reason. Known for its dense trichome coverage, pungent kush aroma, and sky-high resin output, this strain is a dream for making full-spectrum concentrates. A phenotype of OG Kush selected for its stability and oil production, OG 18 Kush delivers classic earthy, pine, and diesel notes with a heavy, sedating high that hits the body hard while calming the mind.

Its sticky buds are coated in resin and packed with terpenes like Myrcene, Limonene, and Caryophyllene making it ideal for both solvent-based and solventless extractions. Whether you’re pressing it into rosin or washing it for hash, OG 18 Kush yields thick, flavorful, and potent extracts that capture everything connoisseurs love about OG genetics.

Honey Banana Cannabis Extraction

Honey Banana is a resin powerhouse bred for flavor and yield. A cross of Honey Boo Boo x Strawberry Banana, this strain explodes with sweet tropical notes, banana cream, and sugary honey. Its extreme trichome coverage and syrupy resin make it ideal for rosin pressing and live extracts with incredible terpene retention. Effects are euphoric, mellow, and long-lasting.

Zoap Cannabis Extraction

Zoap Cannabis Extraction delivers exotic, soapy-sweet fruit notes with floral candy undertones and crazy resin production. This hybrid crosses Rainbow Sherbet x Pink Guava and is prized in hash circles for its dense trichome coverage, insane bag appeal, and full-spectrum aroma. Perfect for fresh frozen hash or live rosin with stunning color and nose.

RS11 Cannabis Extraction

RS11 Cannabis Extraction (Rainbow Sherbet #11) is one of the most talked-about extraction strains today. Its gassy fruit terps, velvety texture, and dripping resin make it ideal for solventless hash and high-end live resin. A cross of Pink Guava x OZK, RS11 blends exotic funk with clean, sweet citrus—perfect for flavorful dabs and rich aroma in jars.

Ooze Cannabis Extraction

Ooze Cannabis Extraction is dessert weed with extraction-level resin. Known for its creamy vanilla, doughy funk, and buttery gas, this strain oozes flavor and finishes with a frosted blanket of trichomes. Its balanced hybrid structure and exotic terpene blend make it perfect for bubble hash and cold cure rosin with smooth, cakey flavor.

Jealousy Cannabis Extraction

Jealousy Cannabis Extraction (Sherbet Bx1 x Gelato 41) is an award-winning strain known for its complex gas-fruit funk and incredibly thick trichome production. With layered flavors of creamy berry, citrus, and earthy kush, it delivers high returns in live rosin and BHO. Its colorful buds and rich terp profile make it a go-to for craft extractors.

Horchata Cannabis Extraction

Horchata Cannabis Extraction blends creamy vanilla, earthy spice, and floral sweetness into a concentrate-lover’s dream. A hybrid of Mochi Gelato x Jet Fuel Gelato, this strain produces greasy trichomes, thick terps, and a dreamy, smooth flavor ideal for cured rosin, sugar wax, or live extract jars with unbeatable aroma.

Cereal Milk Cannabis Extraction

Cereal Milk Cannabis Extraction is a fan-favorite in the extraction world thanks to its dessert terps, heavy crystal coverage, and balanced hybrid profile. With creamy fruit notes reminiscent of sweet milk left in the cereal bowl, it’s perfect for fresh press rosin, badder, and live resin lovers who crave flavor and smoothness.

FAQs about CO2 Cannabis Extraction Machines

How does a CO2 extraction machine work?

A CO2 extraction machine operates by using supercritical CO2 as a solvent to extract cannabinoids and terpenes from cannabis plants. The process begins by compressing CO2 to a supercritical state, where it exhibits both gas and liquid properties. This supercritical CO2 is then passed through the cannabis material, dissolving the desired compounds. Once the extraction is complete, the CO2 is depressurized, returning to its gaseous state and leaving behind a pure extract.

What are the benefits of CO2 extraction?

CO2 extraction offers several benefits, including the ability to produce high-purity extracts without residual solvents. The process is environmentally friendly, as CO2 is a naturally occurring, recyclable compound. Additionally, CO2 extraction allows for precise targeting of specific compounds, enabling the production of full-spectrum extracts that preserve the plant’s natural profile. This method also ensures safety for both operators and consumers, as CO2 is non-toxic and non-flammable.

What maintenance is required for a CO2 machine?

Regular maintenance is essential to keep a CO2 extraction machine running smoothly. This includes routine inspections of components such as pumps, valves, and seals, as well as lubricating moving parts and replacing worn-out components. Following the manufacturer’s maintenance schedule and addressing issues promptly can prevent unexpected breakdowns and ensure the machine’s longevity. Maintaining open communication with the manufacturer or a qualified technician can also provide valuable support in troubleshooting and resolving any operational issues.