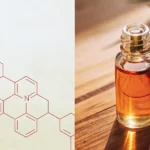

Enzymatic vs Decarboxylation Cannabinoid Conversion

Quick Summary: Cannabinoid activation occurs through two main paths: enzymatic decarboxylation (a slow, natural maceration preserving full-spectrum compounds) and thermal decarboxylation (a fast, heat-driven process). While heat is efficient, enzymatic methods safeguard delicate terpenes and flavonoids for superior infusions.

Enzymatic vs Decarboxylation Cannabinoid Conversion

In the complex chemistry of the cannabis plant, cannabinoids do not start in their active forms. Instead, they exist as acids like THCA and CBDA. To experience their psychoactive or therapeutic effects, these acids must lose a carbon atom. This biological shift is known as decarboxylation. When comparing enzymatic vs decarboxylation cannabinoid conversion, we are looking at two different speeds of the same chemical finish line.

Recommended Strains

Blue Cheese

|

|

THC | 16% - 20% (Medium) |

|

|

Type | Feminized |

|

|

Yield | High |

|

|

Phenotype | 80% Indica / 20% Sativa |

Blue Cheese Autoflower

|

|

THC | 14% - 16% (Medium) |

|

|

Type | Autoflowering |

|

|

Yield | Medium |

|

|

Phenotype | 80% Indica / 20% Sativa |

Enzymatic conversion is the “slow-cooking” version of cannabis science. It happens naturally during the plant’s life cycle and through specialized maceration techniques. Enzymes are biological catalysts that lower the energy needed for a reaction to occur. In a professional setting, this often involves submerged maceration in oils or alcohols over several months. This patient approach ensures that the enzourage effect remains intact, keeping terpenes like Myrcene and Limonene from evaporating under harsh heat.

Thermal decarboxylation, the most common method for making edibles, uses high temperatures to force this reaction in minutes or hours. While highly effective for potency, heat is a double-edged sword. Temperatures exceeding 245°F (118°C) can cause significant degradation of secondary metabolites. If you want a full-spectrum result, understanding the gentle nature of enzymatic pathways is vital for high-end boutique infusions.

Promos & Deals

The Biological Mechanism of Enzymatic Decarboxylation

The enzymatic decarboxylation process is driven by the plant’s internal chemistry during growth and long-term storage. Specific enzymes facilitate the transition from THCA to THC. This is why properly cured flower often tests higher in active THC than fresh “wet” flower. The curing process provides the time needed for these biological workers to finish their task without the destructive force of an oven.

When creating extracts, enzymatic conversion is often achieved through long-term cold maceration. By placing high-quality flower into a carrier like organic olive oil for three to six months, the natural enzymes continue to work. This produces an oil rich in active cannabinoids and preserved flavonoids. Unlike heat-activated oils, which can taste “toasted” or bitter, enzymatic oils retain the vibrant, complex profile of the original strain.

For growers focusing on Information Gain, it is important to note that enzymatic activity is pH and temperature-sensitive. Even in a “cold” process, maintaining a stable environment around 65-70°F (18-21°C) prevents the oils from going rancid while allowing the enzymes to remain active. This is the hallmark of artisanal cannabis pharmacology, favoring quality and chemical diversity over sheer speed.

| Feature | Enzymatic Conversion | Thermal Decarboxylation |

|---|---|---|

| Processing Time | 3 to 6 Months | 30 to 90 Minutes |

| Terpene Retention | Maximum (High Flavor) | Moderate to Low (Heat Loss) |

| Required Energy | Ambient (Natural) | High Heat (Oven/Infuser) |

| Chemical Profile | Full Spectrum / Synergistic | Targeted Potency / Isolated |

| Risk of Degradation | Very Low | High (CBN conversion risk) |

| Best Use Case | Tinctures and Gourmet Oils | Bulk Edibles and Topicals |

The Pros and Cons of Heat-Induced Activation

Decarboxylation via heat is the industry standard for a reason: it is reliable. By applying a consistent DLI (Daily Light Integral) equivalent of thermal energy, we can predict exactly when the majority of THCA has converted to THC. For commercial edible producers, this speed allows for rapid batch testing and consistent dosing across thousands of units.

However, the “Potency over Profile” approach has drawbacks. High-heat decarboxylation often triggers the conversion of THC into CBN (Cannabinol). While CBN has its own sedative benefits, it changes the “high” from a soaring, energetic sativa experience to a heavy, “couch-lock” effect. Furthermore, delicate aromatic compounds are the first to be lost, which is why many commercial edibles require added artificial flavors to mask the “grassy” taste of degraded chlorophyll.

In the debate of enzymatic vs decarboxylation cannabinoid conversion, the user must choose between efficiency and artistry. If you are working with a terpene-rich strain like Purple Haze or Gelato, using an enzymatic maceration prevents the loss of the very traits that make those strains special. Thermal methods are better suited for trim or lower-quality flower where the terpene profile is less of a priority than total THC yield.

Professional Tips for Advanced Conversion

- Burp your maceration: If using the enzymatic path in alcohol, open the jar weekly to prevent gas buildup from slow chemical off-gassing.

- Avoid UV exposure: Light is the enemy of both processes. Whether curing or macerating, use amber glass to prevent UV-induced THC degradation.

- The 70% Rule: For thermal decarboxylation, stop the heat when roughly 70% of the material has changed color. The residual heat will finish the process without burning the terpenes.

- Freeze-drying advantage: Using a freeze-dryer before maceration removes moisture that could interfere with enzymatic activity, accelerating the “slow” path significantly.

- pH Buffering: Adding a tiny amount of citric acid to an oil maceration can help stabilize enzymes and improve the shelf life of the final active cannabinoids.

FAQs about Cannabinoid Conversion

Which process is better for medical patients?

For patients seeking the full medicinal benefits of the plant, enzymatic conversion is often superior. It preserves flavonoids and minor cannabinoids that contribute to the entourage effect. Thermal decarboxylation is better for those who need high-potency THC quickly for immediate relief, but it may lack the broader chemical diversity found in slow-processed oils.

Can I combine both enzymatic and thermal methods?

Yes, many professionals use a “hybrid” approach. They might start with a very short, low-heat thermal cycle (around 200°F) to jumpstart the carboxyl removal, then finish with a 4-week maceration. This balances speed with terpene preservation, though it requires careful monitoring to ensure the oil doesn’t reach a point of diminishing returns in potency.

Does enzymatic conversion work for CBD?

Absolutely. CBD-acid (CBDA) converts to active CBD through enzymatic pathways just like THCA. Because CBD is often used for its anti-inflammatory properties, the preservation of terpenes like Beta-Caryophyllene (which also acts on the endocannabinoid system) through enzymatic methods makes the final product much more effective for inflammation than heat-blasted CBD isolates.