In the world of cannabis cultivation, maintaining an optimal growing environment is crucial for ensuring the health and potency of your plants. One of the key components in managing this environment is the use of charcoal filters. This article explores the importance of charcoal filters in cannabis grow rooms, detailing their benefits, types, installation, and much more to guide both novice and expert growers.

What is a Charcoal Filter?

Charcoal filters, often referred to as activated carbon filters, are a critical tool in air purification, especially in environments like cannabis cultivation where air quality directly impacts plant health and product purity. Marijuana charcoal filter systems are particularly valued for their ability to neutralize strong odors. These filters utilize a special form of carbon that has been processed to have an increased surface area. This processing enhances the carbon’s ability to adsorb — that is, to bind substances to its surface odors, contaminants, and even certain chemicals from the air.

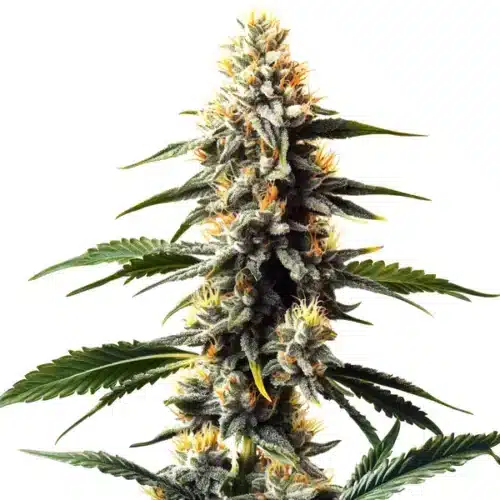

Recommended Strains

Critic Boom

THC: 20% - 25%

THC: 20% - 25% Type of seed: Feminized

Type of seed: Feminized Phenotype: Mostly Sativa

Phenotype: Mostly Sativa Day to flower: 8 - 10 weeks

Day to flower: 8 - 10 weeks

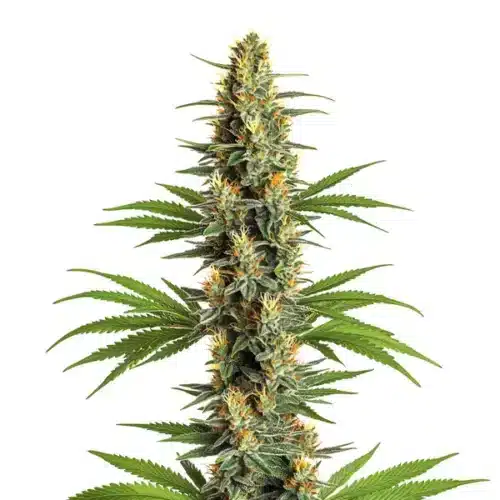

Critical 2.0

THC: 18% - 22%

THC: 18% - 22% Type of seed: Feminized

Type of seed: Feminized Phenotype: Mostly Indica

Phenotype: Mostly Indica Day to flower: 8 - 10 weeks

Day to flower: 8 - 10 weeks

Activation Process: The carbon in charcoal filters is “activated” through a treatment process that involves exposing the carbon to very high temperatures and certain gases that cause the carbon to develop a porous texture. This texture dramatically increases the surface area available for adsorption. To put it in perspective, just one gram of activated carbon can have a surface area of 500–1500 m², which is roughly the size of a tennis court. This extensive surface area allows the filter to capture a vast amount of contaminants compared to its size.

How It Works: When air passes through a charcoal filter, the pollutants in the air are trapped in the pores of the carbon substrate. The effectiveness of a charcoal filter depends on the flow rate and temperature of the air, as well as the concentration of contaminants. Lower flow rates and cooler air typically increase the effectiveness of adsorption.

Applications in Cannabis Cultivation: In the context of cannabis cultivation, these filters are primarily used to manage the strong, distinctive odors produced by cannabis plants. They also play a crucial role in trapping spores, pollen, and other particulates that could harm plants or complicate the cultivation environment. By ensuring that the air remains clean and less detectable from outside the grow area, charcoal filters also aid in compliance with local regulations concerning odor control.

Promos & Deals

Why Use Charcoal Filters in Cannabis Cultivation?

Charcoal filters, specifically those utilizing activated carbon, are an indispensable tool in the arsenal of cannabis cultivators. The reasons for their widespread use are deeply rooted in the unique demands of cannabis cultivation environments, where control over air quality significantly impacts plant health, compliance with regulations, and the overall quality of the final product. Below, we delve into the various advantages of employing charcoal filters in cannabis grow rooms.

Odor Control

One of the most compelling reasons to use charcoal filters in cannabis cultivation is their unparalleled ability to control odors. Cannabis plants, especially during the flowering stage, produce pungent terpenes and odorous compounds that can be overpowering and potentially problematic, especially in urban or residential areas. Activated carbon in charcoal filters effectively absorbs these odors, ensuring that the air leaving the grow room remains neutral and free from any smell that could attract unwanted attention or complaints.

Air Purity

Beyond odor control, charcoal filters play a critical role in purifying the air circulating within and exiting the grow room. These filters trap airborne pollutants such as dust, mold spores, and pollen, which could otherwise compromise plant health or exacerbate issues like mold growth on plants. This level of air filtration is crucial for maintaining a clean and disease-free environment, promoting healthy growth and maximizing yield quality.

Compliance with Regulations

Many regions with legal cannabis cultivation have strict regulations regarding odor control and environmental impact. Employing charcoal filters helps cultivators comply with these legal requirements, preventing the emission of strong cannabis odors into the surrounding area, which is often a stipulation of cultivation licenses. Compliance not only ensures the ongoing legality of the operation but also fosters good community relations.

Protection Against Contaminants

The activated carbon in charcoal filters also helps to remove potentially harmful volatile organic compounds (VOCs) and other chemical pollutants from the air. These substances can be introduced through various means, such as off-gassing from new plastic components, paints, or other building materials used in the grow room setup. By capturing these chemicals, charcoal filters safeguard both plant and human health, contributing to a safer consumption product and work environment.

Maintenance of Growing Conditions

Charcoal filters contribute to the stability of the growing environment by preventing the ingress of external contaminants. Carbon filters weed setups are essential for maintaining air quality and optimal growing conditions. This control helps maintain the integrity of the grow room’s micro-environment, ensuring that temperature, humidity, and CO2 levels can be managed more effectively without the interference of external air factors. Stable conditions are vital for optimal plant growth and cannabinoid production.

Scalability and Cost-Effectiveness

While there are various air purification systems available, charcoal filters remain a cost-effective solution for growers of all sizes. They are relatively inexpensive to install and maintain, especially compared to more complex air purification systems. This scalability makes charcoal filters accessible for home growers and commercial operations alike, providing a practical solution that fits a range of budgetary and operational scales.

Types of Charcoal Filters Used in Cannabis Cultivation

Granular Activated Carbon Filters

Granular Activated Carbon (GAC) filters are widely regarded as the gold standard in air purification for cannabis cultivation facilities. These filters utilize small granules of carbon, which are extremely porous and have a large surface area. This allows them to effectively absorb and trap organic chemicals, odors, and other airborne pollutants that are common in grow rooms.

Advantages of Granular Activated Carbon Filters:

- High Efficiency: GAC filters are highly effective at odor control, making them ideal for maintaining discretion in cannabis cultivation.

- Broad Spectrum Purification: These filters capture a wide range of contaminants, helping to improve the overall air quality and protect the plants from various airborne pathogens.

- Customizability: The size of the carbon granules can be adjusted depending on specific needs, which means they can be tailored to maximize efficiency for different sizes and types of grow rooms.

Challenges:

- Maintenance: GAC filters require regular replacement of the carbon to maintain effectiveness, which can add to operational costs.

- Dust Formation: Over time, the movement of air can cause the carbon granules to break down into dust, which might require additional filtration steps to manage.

Block Carbon Filters

Block carbon filters are made from powdered activated carbon that is compressed into a solid block. They are denser than granular activated carbon filters and typically have a smaller pore size, which allows for finer filtration.

Advantages of Block Carbon Filters:

- Longevity: Due to their density, block carbon filters generally last longer than granular versions before needing replacement.

- Reduced Bypass: With no spaces between granules, block filters provide a more uniform filtration matrix, reducing the chance of contaminants bypassing the carbon.

- Better for Smaller Particles: The fine pore structure of block filters makes them particularly good at capturing smaller particulate matter, which can be beneficial for controlling smaller dust and spores.

Challenges:

- Reduced Air Flow: The density of block filters can restrict air flow more than granular filters, potentially requiring more powerful fans or additional filters to maintain adequate ventilation.

- Higher Initial Cost: Block filters are generally more expensive upfront due to their manufacturing process and materials used.

Comparing Effectiveness and Cost

When deciding between granular and block carbon filters for cannabis cultivation, growers must consider their specific needs:

- For Large-Scale Operations: Granular activated carbon filters might be more cost-effective and easier to scale up, given their efficiency in handling large volumes of air and odors.

- For Premium Small-Scale Indoor Operations: Block carbon filters might be preferable for their finer filtration capabilities, which can be crucial in highly controlled environments where every aspect of air quality is monitored.

Each type of charcoal filter offers distinct advantages and trade-offs. The choice largely depends on factors such as the size of the cultivation area, budget constraints, and specific air quality requirements. Both types of filters are essential tools in managing the air quality of a cannabis cultivation environment, ensuring that the plants remain healthy and the operation stays compliant with local regulations regarding odor control.

How Charcoal Filters Enhance Cannabis Plant Health

Purification of Air

Charcoal filters are integral to creating a clean air environment within cannabis grow rooms. A carbon filter cannabis system ensures the removal of harmful particulates and odors effectively. These filters utilize activated carbon which has a porous texture, ideal for trapping contaminants such as dust, pollen, and even chemical residues that can volatilize from agricultural chemicals used within the grow room. By capturing these pollutants, charcoal filters ensure that the air circulating around the cannabis plants is pure and free from elements that could potentially harm the plants’ stomata (pores) and interfere with their ability to breathe and transpire normally.

Prevention of Pests and Pathogens

Pests and pathogens are among the biggest threats in any form of agriculture, and cannabis cultivation is no exception. Spores from molds and fungi can easily become airborne and, if inhaled by cannabis plants, can lead to widespread disease in the grow room. Charcoal filters significantly reduce this risk by filtering out these spores from the air, thereby helping to maintain a sterile environment. Carbon filters for weed cultivation are also effective in keeping contaminants at bay. This preventative measure is crucial not only for maintaining the health of the plants but also for safeguarding the final product’s quality, ensuring it is free from mold and other contaminants that could pose health risks to consumers.

Optimizing Grow Room Conditions

The ability of charcoal filters to maintain a consistent air quality helps stabilize the grow room’s microclimate. Cannabis plants thrive in environments where temperature and humidity levels are controlled, as fluctuations can stress the plants, making them more susceptible to diseases and reducing their yield and potency. Charcoal filters aid in controlling the odors and potential pollutants, which might otherwise necessitate frequent changes in air exchange rates that could destabilize these environmental parameters. This stability is essential for optimizing photosynthesis and ensuring that the plants can produce as much biomass and as many cannabinoids as possible.

Moreover, the removal of odors through charcoal filtration is particularly beneficial for indoor cannabis operations situated in urban areas or close to other businesses and residential properties, where the strong scent of flowering cannabis plants might attract unwanted attention or complaints. This aspect of charcoal filtration not only enhances the health and yield of the cannabis plants by allowing growers to maintain an optimal growing environment discreetly but also helps in complying with local regulations regarding odor control.

These multifaceted benefits underscore the essential role of charcoal filters in not only protecting but also enhancing the overall health and productivity of cannabis plants in controlled cultivation settings.

Installation and Maintenance of Charcoal Filters

Maintaining a clean and effective air filtration system is crucial for the success of any cannabis cultivation operation. Charcoal filters, known for their robust odor-absorbing capabilities, play a vital role in this process. Proper installation and regular maintenance not only extend the life of these filters but also ensure they perform at their peak efficiency. Here’s a detailed guide on how to install and maintain charcoal filters in a cannabis grow room.

Step-by-Step Installation Guide

- Choose the Right Filter Size and Type: The first step is to select a charcoal filter that matches the size of your grow room and your exhaust system. The filter’s capacity must be sufficient to handle the total volume of air in the space, typically measured in cubic feet per minute (CFM).

- Positioning the Filter: Install the charcoal filter at a point where it can effectively treat the air leaving the grow room. This is usually at the exhaust end of your ventilation setup. Ensure that the filter is accessible for easy maintenance and replacement.

- Secure the Filter: Most charcoal filters are designed to be used with an inline fan. Attach the filter directly to the fan for efficient air movement. Use durable duct clamps and airtight ducting to connect the filter to the fan, ensuring there are no air leaks, which could reduce the efficiency of the filter.

- Double-Check for Airflow Direction: Charcoal filters have a specific direction for airflow, usually indicated by arrows on the filter body. Ensure that the air flows through the filter and not in the opposite direction to maximize efficiency.

- Test the System: Once installed, turn on the ventilation system to check for any air leaks or drops in pressure. Adjust the setup as necessary to ensure optimal performance.

Maintenance Tips for Longevity and Efficiency

- Regular Inspection: Check the charcoal filter every few months for signs of wear or saturation. A simple visual inspection can help identify when the filter medium is becoming clogged with particulates.

- Cleaning the Pre-Filter: Many charcoal filters come with a pre-filter, which catches larger particles before they reach the charcoal layer. Clean or replace this pre-filter regularly, according to the manufacturer’s instructions, to maintain air flow and protect the main filter.

- Replacement Schedule: Charcoal filters need to be replaced once they can no longer effectively absorb odors. This typically occurs every 12 to 18 months, depending on usage, but may vary based on the specific conditions of your grow room. Always follow the manufacturer’s guidelines for replacement.

- Monitor Performance: Keep an eye on the overall environment in your grow room. Any increase in odors or changes in humidity and temperature levels might indicate that your filter is failing and needs attention.

- Proper Disposal: When replacing your old charcoal filter, ensure you dispose of it responsibly. Some components of the filter can be recycled, so check with local disposal regulations to minimize environmental impact.

Common Issues and Troubleshooting

- Reduced Airflow: If you notice a significant drop in airflow through the filter, check for blockages in the pre-filter or ducting. Replacing a clogged pre-filter can restore normal airflow.

- Persistent Odors: Should odors persist despite a new or recently replaced filter, ensure the filter is correctly sized for your room and that there are no leaks in the ducting. Double-check the installation to ensure all fittings are secure.

- Humidity Issues: High humidity can reduce the lifespan of a charcoal filter. If your grow room is particularly humid, consider using a dehumidifier to help extend the life of your filter.

Proper installation and diligent maintenance of your charcoal filters will ensure that your cannabis cultivation environment remains clean, controlled, and conducive to producing high-quality cannabis. By following these guidelines, growers can effectively manage the air quality in their grow rooms, leading to healthier plants and a more successful harvest.

Comparing Charcoal Filters with Other Filtration Methods

When cultivating cannabis indoors, maintaining pure, clean air is essential not only for the health of the plants but also to control odors and ensure compliance with local regulations. While charcoal filters are a popular choice for cannabis growers, it’s beneficial to explore how they stack up against other air filtration methods such as HEPA filters and UV air purifiers.

HEPA Filters

HEPA (High-Efficiency Particulate Air) filters are renowned for their ability to capture 99.97% of particles that are 0.3 microns in diameter. This makes them highly effective in removing dust, pollen, mold spores, and some bacteria from the air.

Pros:

- High Efficiency: HEPA filters are extremely effective at capturing a wide range of airborne particles, including many of the smallest particulate contaminants.

- Allergen Control: Excellent for removing allergens, making them ideal for environments where air quality is crucial for health reasons.

Cons:

- No Odor Control: Unlike charcoal filters, HEPA filters do not remove odors or volatile organic compounds (VOCs), which are prevalent in cannabis grow rooms.

- Maintenance Cost: HEPA filters can be more expensive to replace and often require more frequent changes depending on the environment.

UV Air Purifiers

UV air purifiers use ultraviolet light to kill or deactivate airborne pathogens and microorganisms, making them an excellent supplement to filtration methods that physically remove particles.

Pros:

- Pathogen Control: UV purifiers are highly effective at controlling bacteria and viruses, which can be crucial in preventing the spread of plant diseases in a grow room.

- Operational Efficiency: These units can operate continuously and generally require less maintenance compared to filter-based systems.

Cons:

- Limited Filtration: UV purifiers do not remove any physical particles from the air. They must be used in conjunction with other filters to achieve comprehensive air quality control.

- Potential Safety Concerns: Direct exposure to UV-C light can be harmful to both plants and humans, requiring careful containment and placement in grow rooms.

Comparing Effectiveness and Cost

When considering which filtration method to employ in a cannabis cultivation environment, both the specific needs of the grow room and the overall budget must be taken into account.

- Charcoal Filters are most effective for controlling odors and VOCs, making them indispensable in environments where odor management is legally or socially necessary. However, they do not address particulates or pathogens effectively on their own.

- HEPA Filters are suited for environments where particle contamination could harm the plants or product quality. Their inability to control odors makes them a secondary choice for cannabis operations unless paired with a charcoal filter.

- UV Air Purifiers offer excellent control over pathogens but should be used as a supplementary measure, combined with HEPA or charcoal filters to ensure comprehensive air quality management.

Cost-efficiency also varies; charcoal filters are relatively inexpensive but need to be replaced depending on the volume of odors and contaminants. HEPA filters can be costly upfront and might require more frequent replacements depending on environmental conditions. UV purifiers have lower ongoing costs but might require a higher initial investment.

FAQ About Charcoal Filters in Cannabis Cultivation

How often should I replace the charcoal filter in my cannabis grow room?

The frequency of replacing your charcoal filter depends on several factors including the volume of air being filtered, the size of the grow room, and the intensity of odors produced by your plants. Generally, it is recommended to replace the filter every 4 to 6 months, but this can vary. For optimal performance, monitor the airflow and odor control, and replace the filter when you notice a decrease in effectiveness.

Can I clean and reuse a charcoal filter?

Charcoal filters are not typically reusable since the activated carbon that traps the contaminants eventually becomes saturated. Once saturated, it cannot be effectively cleaned or reactivated. Attempting to clean the filter can also compromise its integrity and effectiveness. It’s best to replace them with new ones to maintain the highest air quality in your grow room.

What size charcoal filter do I need for my grow room?

The size of the charcoal filter needed for your grow room depends on the volume of air that needs to be scrubbed. A good rule of thumb is to choose a filter that can handle at least the cubic footage of your grow space in minutes. For example, if your grow room is 1,000 cubic feet, look for a filter rated for at least 1,000 CFM (cubic feet per minute). This ensures that the air in your entire grow room is filtered once every minute.

Does the use of a charcoal filter affect the temperature or humidity in my grow room?

Charcoal filters themselves do not significantly affect the temperature or humidity. However, the ventilation system used in conjunction with the charcoal filter can influence these conditions. Ensure that your ventilation setup is correctly balanced to maintain optimal temperature and humidity levels for cannabis cultivation.

Are charcoal filters effective against mold and mildew in grow rooms?

Charcoal filters are effective at removing spores and odors from the air, which can help in controlling mold and mildew. However, they are just one part of a comprehensive approach to mold and mildew prevention, which should also include controlling humidity levels, ensuring proper airflow, and maintaining cleanliness in the grow area.

Can I use any charcoal filter for my cannabis grow room, or are there specific types meant for this purpose?

While there are many types of charcoal filters available, it’s important to choose one specifically designed for use in grow rooms. These filters are typically built to handle the high humidity environments and strong odors associated with cannabis cultivation. They often feature thicker beds of activated carbon for better odor absorption and longer life spans.

How do I know if my charcoal filter is no longer effective?

Signs that your charcoal filter may need to be replaced include a noticeable return of odors that were previously controlled, reduced airflow through the filter, or an increase in humidity or mold issues in the grow room. If you observe any of these changes, it is likely time to replace the filter.

Each of these questions and answers aims to provide practical and detailed insights to help both novice and experienced cannabis cultivators make the most of their charcoal filtering systems.