CBGA to THCA Enzyme Reaction

Quick Summary: The CBGA to THCA enzyme reaction is the biological process where THCA synthase converts “mother cannabinoid” CBGA into THCA. Optimizing temperature (75-80°F), maintaining a pH of 6.0, and using specific light spectrums are critical for maximizing this enzymatic catalysis and final THC potency.

CBGA to THCA Enzyme Reaction

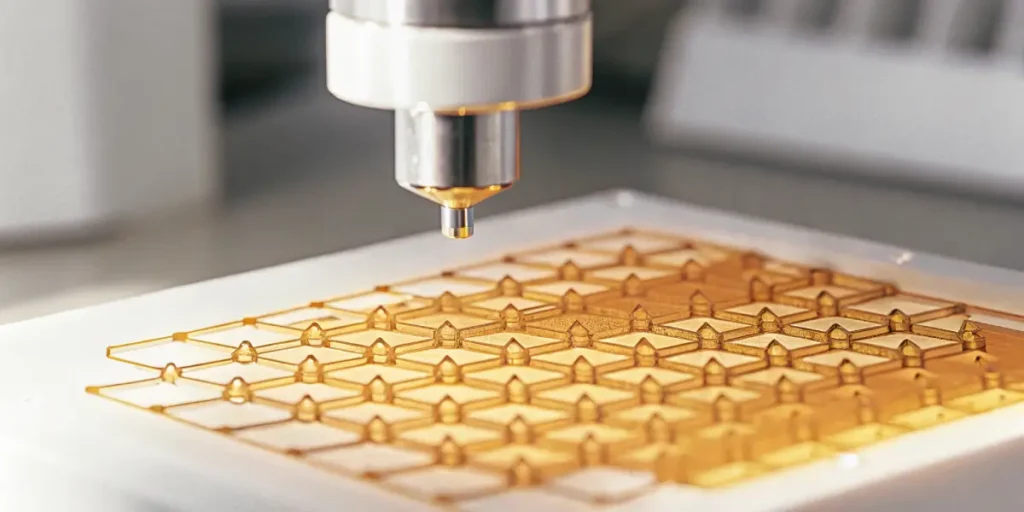

The CBGA to THCA enzyme reaction is the fundamental biosynthetic pathway that determines the psychoactive potential of the cannabis plant. At the heart of this process is Cannabigerolic Acid (CBGA), often called the “mother cannabinoid.” Through a process known as enzymatic catalysis, the plant uses a specific protein called THCA synthase to reconfigure the molecular structure of CBGA into Tetrahydrocannabinolic Acid (THCA). This happens primarily within the stalked glandular trichomes during the flowering stage.

Recommended Strains

Biologically, enzymes act as specialized biological tools. In the CBGA to THCA biosynthesis process, the THCA synthase enzyme lowers the activation energy required for the chemical bond changes to occur. This means the plant can produce high levels of THCA without needing extreme heat or energy. For growers, ensuring that the plant has the internal resources, specifically proper auxins and gibberellins, is vital, as these growth hormones help regulate the system of enzymatic reactions that drive cannabinoid production.

Environmental stability is the “fuel” for this reaction. If a plant is stressed by thirst or light fluctuations, the CBGA to THCA enzymatic reaction mechanism can slow down or prioritize other survival tasks. This leads to “clear” trichomes that never fully reach maturity. High-quality genetics, such as those from Blimburn Seeds, provide the genetic “blueprint” that ensures the THCA synthase enzyme is active and abundant throughout the late flowering phase.

Promos & Deals

The Role of pH and Hormones in Biosynthesis

Maintaining a stable pH of 6.0 in the root zone is fundamental for enzymatic vigor. Enzymes are highly sensitive to their chemical environment. If the pH fluctuates too far from the ideal range, the enzymes can change shape, a process called denaturation, making them unable to bind with CBGA. A steady pH ensures that the plant can absorb essential micro-elements like Magnesium, which acts as a cofactor in many enzymatic steps within the pathway of CBGA to THCA enzyme reaction.

Furthermore, the interaction between auxins and gibberellins plays a hidden role in potency. Auxins help define the growth of the trichome stalks, while gibberellins influence cell expansion. By promoting a healthy hormonal balance, the grower increases the “factory space” (trichome volume) where the CBGA to THCA transformation takes place. Without these hormones working in harmony, even the best genetics will produce smaller resin glands with lower cannabinoid concentrations.

| Technical Factor | CBGA to THCA Reaction | Vegetative Growth | Decarboxylation Phase |

|---|---|---|---|

| Main Driver | THCA Synthase Enzyme | Chlorophyll Production | Thermal Energy (Heat) |

| Ideal pH | 6.0 (Substrate) | 5.8 – 6.2 | N/A (Post-Harvest) |

| Key Hormones | Gibberellins / Auxins | Auxins (Apical) | None (Chemical) |

| Light Requirement | High PPFD (Flower) | Moderate PAR | None (Avoid UV) |

| Optimal Temp | 75°F – 80°F | 70°F – 85°F | 220°F+ (Activation) |

| Primary Precursor | CBGA | Nitrogen (N) | THCA |

Optimizing CBGA to THCA Transformation for Maximum Yield

To truly maximize the CBGA to THCA biosynthesis process, growers must look at the “Entourage Effect.” This concept suggests that cannabinoids work better when paired with specific terpenes like Myrcene, Limonene, and Caryophyllene. During the late flowering stage, the plant is simultaneously producing these aromatic compounds and cannabinoids. Harsh temperatures above 85°F can cause these delicate terpenes to evaporate, which may also prematurely degrade the enzymes responsible for the CBGA to THCA transformation.

Using CO2 enrichment is another advanced tactic. When CO2 levels are increased to 1200-1500 ppm, the plant’s metabolic rate increases. This forces a higher turnover in the CBGA to THCA enzymatic reaction mechanism, allowing the plant to synthesize THCA at a faster rate. However, this only works if the light intensity (PPFD) is high enough to support the increased metabolism. Without enough “light energy,” the extra CO2 cannot be processed, and the enzymatic reaction remains at its baseline level.

Professional Tips for Master Growers

- Monitor Trichome Color: Use a 30X to 60X microscope. Peak CBGA to THCA conversion is often indicated when 50% of the trichomes are milky white and 50% are translucent.

- Avoid Late-Flower Stress: While minor stress can increase resin, over-pruning after week 4 of flower can stop enzymatic reactions, leaving you with “airy” buds.

- Temperature Control: Keep night temperatures about 10-15 degrees cooler than day temps. This helps preserve the enzymes and prevents the breakdown of the THCA already produced.

- Flush Properly: Stop fertilizing 10-14 days before harvest. This forces the plant to use up stored nutrients, which often clears the way for a final burst in CBGA to THCA biosynthesis.

- Root Zone Health: Healthy white roots are essential for transporting the water needed for photosynthesis, the engine that powers all enzymatic reactions.

FAQs

What is the CBGA to THCA enzyme reaction?

It is the biological process where the THCA synthase enzyme converts Cannabigerolic Acid (CBGA) into Tetrahydrocannabinolic Acid (THCA). This happens within the plant’s resin glands. This reaction is vital because it determines the final THC potency. Proper light and temperature are required to keep these enzymes working efficiently during the flowering stage.

How does enzyme catalysis work in CBGA to THCA conversion?

Enzyme catalysis works by using the THCA synthase protein as a biological machine. It binds with the “mother molecule” CBGA and re-arranges its chemical bonds to create THCA. The enzyme acts as a catalyst, meaning it speeds up this natural process significantly without being destroyed, allowing the plant to produce high amounts of cannabinoids over time.

What factors affect the CBGA to THCA transformation?

Key factors include temperature, light intensity (PPFD), and root zone pH. Specifically, a pH of 6.0 is ideal for nutrient uptake that supports enzyme health. Additionally, the presence of gibberellins and auxins helps regulate the CBGA to THCA biosynthesis process. High temperatures above 85°F can damage these enzymes and lower the overall quality of the harvest.

Why is the CBGA to THCA biosynthesis process important for growers?

This process is the only way a cannabis plant can produce THCA, which later becomes psychoactive THC. If the biosynthesis process is interrupted by stress or poor nutrition, the plant will have low potency. Master growers focus on optimizing this reaction to ensure their flower has the desired cannabinoid and terpene profiles for a strong entourage effect.

How can growers optimize the CBGA to THCA enzyme reaction?

Growers can optimize this reaction by maintaining a stable environment with temperatures between 75-80°F and a pH of 6.0. Using high-quality seeds from providers like Blimburn Seeds ensures the plant has a strong genetic drive for enzyme production. Proper watering and the use of CO2 can also help the plant reach its full genetic potential for THCA production.