Cannabis Extraction Equipment: Types, Tools, and Technological Advances

Cannabis extraction equipment plays a pivotal role in the burgeoning cannabis industry. With the diverse range of products available on the market today, knowing the various types of equipment is essential for anyone looking to delve into the world of cannabis extraction. From basic tools to advanced machinery, these devices are designed to efficiently separate desired compounds from the plant material.

The types of equipment can vary significantly based on the extraction method employed, be it solvent-based, solventless, or even the more traditional methods. Each type of equipment is tailored to specific extraction processes, influencing factors like yield, purity, and safety. Whether you’re a small-scale producer or part of a large industrial operation, choosing the best cannabis extraction equipment for your needs is the first step towards successful cannabis extraction.

Recommended Strains

CBD Sour Tangie (1:25)

|

|

CBD | 6% – 8% (Low) |

|

|

Type | CBD Feminized |

|

|

Yield | Low |

|

|

Phenotype | 10% Indica / 90% Sativa |

CBD Tangie (1:15)

|

|

CBD | 12% – 14% (Medium) |

|

|

Type | CBD Feminized |

|

|

Yield | Medium |

|

|

Phenotype | 50% Indica / 50% Sativa |

Functions and Roles in Extraction

Understanding the functions and roles of cannabis extraction equipment is crucial for optimizing the extraction process. These tools not only aid in extracting cannabinoids and terpenes but also ensure the quality and consistency of the final product. For instance, some equipment is designed to handle the initial phase of extraction, breaking down the plant material to prepare it for further processing.

Other pieces of equipment play a role in refining and purifying the extract to meet regulatory standards and consumer preferences. The effectiveness of the extraction process directly correlates with the functionality of the equipment used. Each device, from the smallest accessory to the largest machine, has a specific role that contributes to the overall efficiency and outcome of the extraction process.

Promos & Deals

Key Tools and Devices

Main Extraction Machines

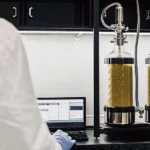

The heart of any extraction operation lies in the main extraction machines. These machines are the workhorses that facilitate the separation of cannabinoids and terpenes from cannabis plants. Popular types include CO2 extractors, hydrocarbon extractors, and ethanol extractors. Each of these has unique advantages and is selected based on the desired end product and operational preferences.

CO2 extractors are favored for their ability to produce high-purity extracts without leaving solvent residues. Hydrocarbon extractors, utilizing butane or propane, are known for their efficiency and cost-effectiveness. Ethanol extractors, on the other hand, offer a balance between purity and operational simplicity. As technology advances, these machines continue to evolve, incorporating features that enhance safety and efficiency.

Supporting Accessories

Supporting accessories are just as important as the main extraction machines. These tools ensure the smooth operation of the entire extraction process. From filtration systems to vacuum pumps, each accessory plays a critical role. Filtration systems are essential for removing impurities and ensuring the clarity of the extract.

Vacuum pumps are used to maintain pressure levels during extraction, preventing contamination and improving the quality of the final product. Other accessories like chillers and heaters help maintain optimal temperatures, crucial for preserving the integrity of cannabinoids and terpenes. By investing in quality supporting accessories, operators can significantly enhance the efficiency and outcome of their extraction processes.

Selection and Maintenance

How to Choose the Right Equipment

Selecting the right cannabis extraction equipment can be a daunting task. With the plethora of options available, it’s important to consider factors such as the scale of operation, budget, and desired end product. It’s also vital to evaluate the extraction method that aligns with your goals, whether you’re aiming for concentrates, oils, or edibles.

Consulting with industry experts and conducting thorough research can lead to informed decisions. The right equipment will not only ensure high-quality extracts but also increase operational efficiency. Remember to prioritize equipment that complies with industry standards and offers the latest technological advancements. Making the right choice can set the foundation for a thriving extraction operation.

Best Maintenance Practices

Maintaining cannabis extraction equipment is crucial for operational longevity and safety. Regular maintenance helps prevent breakdowns, ensures consistent performance, and extends the lifespan of the equipment. Implementing a routine maintenance schedule is an effective way to keep equipment in top shape.

Cleaning is a fundamental aspect of maintenance. Residue build-up can impede functionality and compromise the quality of the extracts. Lubrication and inspection of moving parts are also vital, as they reduce wear and tear. Additionally, keeping detailed maintenance logs can help identify patterns and preempt potential issues. By adhering to best maintenance practices, operators can maximize the efficiency and reliability of their equipment.

Technological Advances in Extraction

Recent Innovations

The cannabis industry is witnessing rapid technological advancements, especially in extraction equipment. Innovations such as closed-loop systems, automation, and real-time monitoring are transforming traditional extraction methods. Closed-loop systems have revolutionized safety and efficiency by preventing solvent loss and reducing environmental impact.

Automation is another game-changer, allowing for precise control over the extraction process and minimizing human error. Real-time monitoring systems provide instant feedback on key parameters, enabling operators to make informed adjustments on the fly. These technological advances not only improve the quality and consistency of extracts but also contribute to safer and more sustainable extraction practices.

Impact on Extraction Efficiency

Technological advances have a profound impact on the efficiency of cannabis extraction. By incorporating state-of-the-art equipment, operators can achieve higher yields and purer products. Enhanced control over extraction variables ensures that cannabinoids and terpenes are preserved to the fullest extent possible.

Efficiency gains are not limited to the extraction phase alone; they extend to post-extraction processes as well. Improved equipment designs and functionalities facilitate faster processing times, reducing operational costs and increasing profitability. As technology continues to evolve, the potential for even greater efficiency in cannabis extraction remains promising.

FAQs about cannabis extraction equipment

What are the essential tools for cannabis extraction?

Essential tools for cannabis extraction include main extraction machines like CO2, hydrocarbon, and ethanol extractors, as well as supporting accessories such as filtration systems and vacuum pumps. These tools work together to efficiently separate cannabinoids and terpenes while ensuring the quality of the final product.

How can I maintain my extraction equipment properly?

Proper maintenance of extraction equipment involves regular cleaning, lubrication, and inspection of moving parts. Implementing a routine maintenance schedule and keeping detailed logs can help identify and address issues before they become significant problems, ensuring consistent performance and longevity.

What recent innovations have improved extraction methods?

Recent innovations in cannabis extraction include closed-loop systems, automation, and real-time monitoring. These advancements have enhanced safety, efficiency, and control over the extraction process, leading to higher quality extracts and more sustainable practices.