Enzyme-Based Solutions for Minor Cannabinoid Production

Enzyme-based solutions for minor cannabinoid production are transforming the way we approach cannabis cultivation. By using enzymes, we can efficiently produce cannabinoids that are less common in traditional cannabis plants. These minor cannabinoids hold potential for various therapeutic applications, making them a valuable addition to any grower’s portfolio.

Enzyme technology in cannabinoid production involves harnessing the power of biocatalysts. Enzymes are proteins that speed up chemical reactions, and they can be engineered to produce specific cannabinoids. This biocatalysis in cannabinoid synthesis is a game-changer, allowing us to create rare compounds without extensive cultivation or extraction processes.

Recommended Strains

Deimos Auto

-

THC: 14% - 16%

-

Type of seed: Autoflowering

-

Phenotype: 25% Sativa / 75% Indica

-

Flavor: Earthy, Fruity, Sweet

-

Life cycle of: 8 - 10 weeks

Cream Auto

-

THC: 16% - 18%

-

Type of seed: Autoflowering

-

Phenotype: 30% Sativa / 70% Indica

-

Flavor: Earthy, Sweet

-

Life cycle of: 8 - 10 weeks

Consider enzyme engineering for rare cannabinoids as a means to unlock new possibilities. By optimizing enzyme reactions for cannabinoids, we can enhance yields and efficiency. This approach is not only innovative but also sustainable, offering a greener method for cannabinoid production compared to traditional chemical synthesis methods.

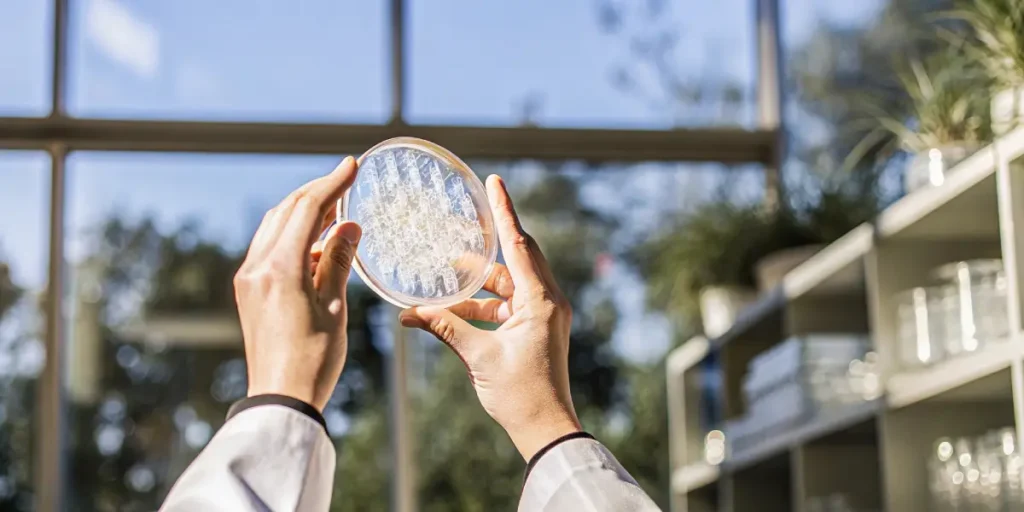

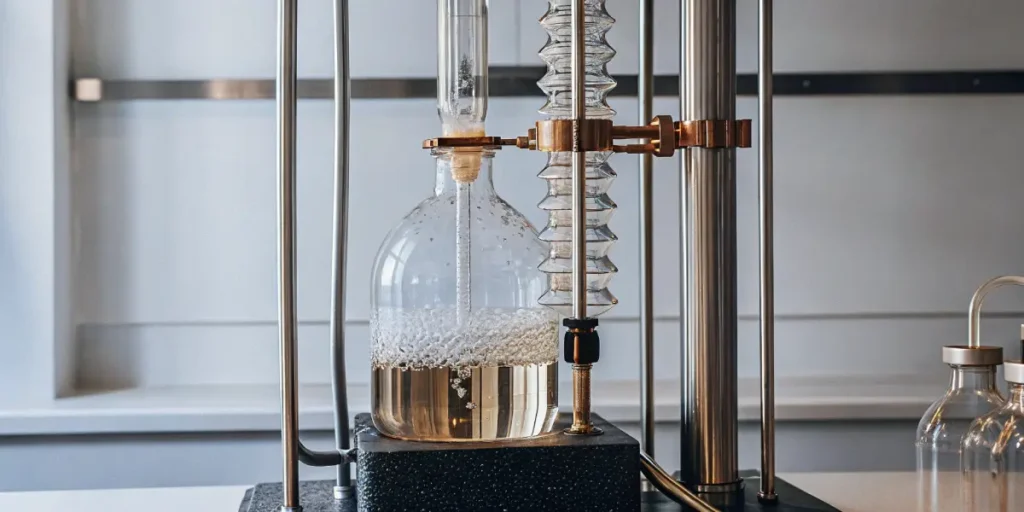

How Enzyme-Based Solutions Work

The process begins with selecting the right enzymes for the job. Different enzymes target different cannabinoid pathways, so knowing which ones to use is crucial. These enzymes can be naturally occurring or engineered for specific tasks, tailoring the production process to desired outcomes.

Once the enzymes are selected, they are introduced to the cannabis plant material or converted substrates. Enzymes act as catalysts, speeding up the conversion of precursors into cannabinoids. This method is highly efficient, reducing both time and resource consumption compared to traditional methods.

Biocatalysis in cannabinoid synthesis is a focal point in this process, as it allows for the selective and efficient production of target cannabinoids. By leveraging enzyme technology in cannabinoid production, growers can produce cannabinoids with greater precision and control. This not only increases the quality of the final product but also ensures a consistent output, which is essential for both medical and recreational markets.

As enzyme engineering for rare cannabinoids progresses, new enzymes are being developed that can operate under a wider range of conditions, further enhancing the versatility of enzyme-based solutions for minor cannabinoid production. This innovation is paving the way for a new era of cannabis cultivation, where sustainability and efficiency are at the forefront.

Benefits of Enzyme-Based Solutions

One significant advantage of enzyme-based solutions is their sustainability. Unlike chemical synthesis, which often requires harsh solvents and conditions, enzyme methods are gentle and environmentally friendly. This aligns with the growing demand for sustainable enzyme methods for cannabinoids.

Enzyme-based solutions also offer precision. Enzymes can be fine-tuned to produce specific cannabinoids, allowing growers to focus on high-value compounds. This precision is essential for creating products tailored to medical or recreational markets.

Moreover, enzyme-based solutions for minor cannabinoid production contribute to reducing waste, as the process can be optimized to use only the necessary substrates and conditions. This reduces the environmental impact and makes the production process more cost-effective in the long run. By optimizing enzyme reactions for cannabinoids, growers can achieve higher yields with less input.

The economic benefits are also notable. With the ability to produce rare cannabinoids more efficiently, growers can tap into new markets and offer a wider range of products. This diversification not only enhances the grower’s portfolio but also meets the increasing consumer demand for unique cannabinoid profiles.

Promos & Deals

Implementing Enzyme-Based Solutions

Implementing enzyme-based solutions requires an knowing of both the scientific and practical aspects. Growers should start by identifying their goals, such as increasing the yield of a specific cannabinoid. From there, selecting the appropriate enzymes and substrates becomes crucial.

Once the implementation plan is in place, monitoring the process is key. This involves regular testing and adjustments to ensure optimal enzyme activity. With proper management, growers can achieve consistent results, enhancing both the quality and quantity of their cannabinoid production.

Successful implementation of enzyme-based solutions for minor cannabinoid production often involves collaboration with experts who specialize in enzyme technology in cannabinoid production. Their insights can guide the selection of the most effective enzymes and help troubleshoot any issues that arise during the process. This partnership can be crucial in achieving the desired outcomes efficiently.

Additionally, investing in research and development can further enhance the implementation process. By staying updated on the latest advancements in enzyme engineering for rare cannabinoids, growers can continually refine their methods and maintain a competitive edge in the ever-evolving cannabis industry.

Choosing the Right Strains

Not all cannabis strains are equally suited for enzyme-based production. It’s essential to choose strains with the right cannabinoid profiles. For instance, strains like Sour Diesel, available at Blimburn Seeds, have unique characteristics that can be amplified with enzyme methods.

Using strains with already diverse cannabinoid profiles allows for greater flexibility in production. This way, you can focus on enhancing specific minor cannabinoids without compromising the overall balance of the plant.

When considering enzyme-based solutions for minor cannabinoid production, it’s also important to evaluate the genetic stability of the chosen strains. Stable genetics ensure that the desired traits are consistently expressed in the resulting plants, which is crucial for maintaining the quality and efficacy of the end product. This genetic stability complements the precision of enzyme technology in cannabinoid production.

Furthermore, the terpene profile of a strain can enhance the overall appeal of the final product. Strains with robust terpene profiles, like Tangie, can benefit significantly from enzyme engineering for rare cannabinoids, as the combination of unique cannabinoids and terpenes can create a more desirable and marketable product.

Challenges and Solutions

Despite their advantages, enzyme-based solutions for minor cannabinoid production present challenges. One common issue is enzyme stability, as enzymes can be sensitive to environmental conditions. Proper storage and handling are essential to maintain their effectiveness.

Another challenge is the initial cost of setting up enzyme-based processes. However, the long-term benefits, including increased yield and sustainability, often outweigh these initial investments. By focusing on optimizing enzyme reactions for cannabinoids, growers can ensure a high return on investment.

To address the challenge of enzyme stability, researchers are continually exploring new formulations and protective techniques that can extend the shelf life and functionality of enzymes. These innovations in enzyme technology in cannabinoid production can significantly enhance the reliability and effectiveness of the production process.

Moreover, the financial hurdle of initial setup costs can be mitigated by seeking partnerships or grants that support sustainable enzyme methods for cannabinoids. These resources can provide the necessary funding to implement enzyme-based solutions, allowing growers to benefit from this cutting-edge technology without bearing the full financial burden upfront.

Addressing Technical Hurdles

Technical hurdles can be addressed through careful planning and research. For instance, collaborating with experts in enzyme technology can provide valuable insights and solutions to common problems. This collaboration can lead to more robust and reliable production processes.

Investing in high-quality enzymes and equipment is another way to overcome challenges. While this may involve higher upfront costs, the resulting efficiency and consistency justify the expense. High-quality inputs lead to high-quality outputs.

Continuous education and staying abreast of new developments in enzyme engineering for rare cannabinoids are critical for overcoming technical challenges. As the field evolves, new techniques and breakthroughs can offer solutions to previously intractable issues, keeping growers at the cutting edge of technology.

Additionally, leveraging data analytics and monitoring systems can enhance the optimization of enzyme reactions for cannabinoids. By collecting and analyzing data from the production process, growers can make informed adjustments to improve efficiency and yield, ensuring the success of enzyme-based solutions for minor cannabinoid production.

FAQs About enzyme-based solutions for minor cannabinoid production

What are enzyme-based solutions for minor cannabinoid production?

Enzyme-based solutions for minor cannabinoid production involve using enzymes to catalyze the formation of cannabinoids that are not abundant in typical cannabis strains. These enzymes can be either naturally occurring or engineered to produce specific cannabinoids, offering an efficient and sustainable way to enhance minor cannabinoid yields.

This approach is gaining popularity due to its precision and environmental benefits. By reducing reliance on traditional chemical methods, enzyme-based solutions provide a cleaner, greener alternative for producing high-value cannabinoids.

In the context of enzyme technology in cannabinoid production, these solutions enable the creation of novel cannabinoids that may not be feasible to produce through traditional cultivation or extraction. This opens up new opportunities for product differentiation and innovation within the cannabis market.

Furthermore, enzyme-based solutions for minor cannabinoid production can be tailored to meet specific market demands, whether for medical applications or recreational use. This adaptability is a significant advantage, allowing producers to respond swiftly to changing consumer preferences and regulatory requirements.

How does biocatalysis in cannabinoid synthesis work?

Biocatalysis in cannabinoid synthesis involves using enzymes as catalysts to accelerate the chemical reactions that produce cannabinoids. These enzymes can be tailored to convert specific precursor compounds into desired cannabinoids, making the process highly efficient and targeted.

This method allows for the production of rare cannabinoids that may not be readily available in natural plant material, expanding the possibilities for therapeutic and recreational cannabis products.

Through enzyme engineering for rare cannabinoids, biocatalysis can be further refined to enhance the efficiency and specificity of enzyme reactions. This refinement ensures that the desired cannabinoids are produced with minimal byproducts, maximizing the purity and potency of the final product.

As research in this area advances, new enzymes and biocatalytic methods continue to emerge, offering even greater potential for enzyme-based solutions for minor cannabinoid production. These innovations hold the promise of more sustainable and economically viable cannabis production methods.

What is enzyme engineering for rare cannabinoids?

Enzyme engineering for rare cannabinoids involves modifying enzymes to enhance their ability to produce uncommon cannabinoids. This process can include altering the enzyme’s structure or introducing mutations that improve its efficiency and specificity.

Through enzyme engineering, growers can access a broader range of cannabinoids, offering new opportunities for product development and differentiation in the cannabis market.

The process of enzyme engineering for rare cannabinoids involves a combination of computational modeling and experimental techniques to identify and implement the most effective modifications. This interdisciplinary approach ensures that the engineered enzymes meet the specific needs of cannabinoid production.

Additionally, as enzyme technology in cannabinoid production continues to evolve, the potential for discovering novel cannabinoids and their therapeutic applications expands, further emphasizing the importance of enzyme engineering in this field.

Why are sustainable enzyme methods for cannabinoids important?

Sustainable enzyme methods for cannabinoids are important because they minimize environmental impact compared to traditional chemical synthesis. These methods use less energy and produce fewer harmful byproducts, aligning with the growing demand for eco-friendly cannabis production.

By adopting sustainable practices, growers can reduce their carbon footprint and contribute to a more sustainable industry, appealing to environmentally-conscious consumers.

The emphasis on sustainability also enhances the overall reputation of the cannabis industry, as consumers and regulators increasingly prioritize environmentally responsible practices. Implementing sustainable enzyme methods for cannabinoids offers a competitive advantage in this context.

Furthermore, sustainable enzyme-based solutions for minor cannabinoid production often result in cost savings over time. By reducing resource consumption and waste, growers can operate more efficiently and economically, enhancing their long-term viability in the market.

How can I optimize enzyme reactions for cannabinoids?

Optimizing enzyme reactions for cannabinoids involves fine-tuning conditions such as temperature, pH, and substrate concentration to maximize enzyme activity. Regular monitoring and adjustments ensure that the enzymes are working at their peak efficiency.

Collaboration with experts and continuous learning are also key to successful optimization. By staying informed about the latest advancements in enzyme technology, growers can maintain competitive and efficient production processes.

Advanced tools and technologies, such as high-throughput screening and computational modeling, are increasingly being used to optimize enzyme reactions for cannabinoids. These tools provide valuable insights into how enzymes interact with substrates, facilitating the identification of optimal conditions for production.

Additionally, investing in research and development to explore new enzyme variants and reaction pathways can lead to further improvements in the efficiency and yield of enzyme-based solutions for minor cannabinoid production. This proactive approach ensures that growers remain leaders in the rapidly evolving cannabis industry.