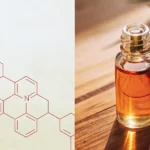

Industrial Enzymes for Cannabinoid Processing

Industrial enzymes for cannabinoid processing are gaining momentum in the cannabis industry. These powerful proteins can significantly enhance cannabinoid extraction efficiency, paving the way for purer, more potent products. Imagine transforming raw cannabis into high-quality oils and concentrates with less waste and fewer resources. It’s like baking a cake and getting more slices from the same ingredients.

For first-time cannabis seed buyers and seasoned growers, knowing enzyme-assisted cannabinoid production techniques can be a game-changer. These enzymes break down plant material, making it easier to extract valuable cannabinoids. The process is akin to unlocking a treasure chest with a key instead of a crowbar. Industrial enzyme solutions for cannabis processing are revolutionizing the way we approach this plant.

Recommended Strains

Killer

|

|

THC | 22% - 26% (High) |

|

|

Type | Feminized |

|

|

Yield | Medium |

|

|

Phenotype | 70% Indica / 30% Sativa |

Grape Killer 99

|

|

THC | 15% - 20% (Medium) |

|

|

Type | Feminized |

|

|

Yield | Medium |

|

|

Phenotype | 40% Indica / 60% Sativa |

Consider strains like Blue Dream, known for its balanced effects and ease of growth. By using enzymes, growers can maximize yield and potency, ensuring every harvest is a success. Enzymes streamline the process, offering a sustainable and efficient alternative to traditional methods.

Enzymes for Cannabinoid Extraction Efficiency

Efficiency is the name of the game when it comes to cannabinoid extraction. Industrial enzymes for cannabinoid processing can enhance this efficiency by breaking down complex molecules within the plant. Think of it like dismantling a LEGO set into individual pieces for easier assembly into something new.

Strains like GG4 can benefit greatly from this method. Known for its high THC content, this strain can yield even more potent extracts when enzymes are used. The enzymes help unlock the full potential of the plant, ensuring growers get the most out of their investment.

- Increased yield from each plant

- Higher purity of extracted cannabinoids

- Reduced processing time and energy

By employing enzymes for cannabinoid extraction efficiency, producers can also ensure a consistent product quality, which is crucial for maintaining brand reputation. The precision in extraction means that each batch of product remains uniform, meeting the high expectations of consumers. As the industry grows, the demand for reliable and repeatable processes becomes even more pressing, and enzymes provide the solution.

Moreover, the integration of industrial enzyme solutions for cannabis processing allows for scalability. As operations expand, the enzymatic processes can be adjusted to handle larger volumes without sacrificing quality or efficiency. This adaptability is key for businesses looking to expand their market presence while maintaining the integrity of their products.

Optimizing Cannabinoid Yield with Enzymes

Optimizing yield is critical for maximizing profit and sustainability. Enzyme-assisted cannabinoid production techniques can help achieve this by ensuring that every part of the plant is utilized. It’s like squeezing every last drop from an orange, ensuring nothing goes to waste.

For growers focused on quality and quantity, industrial enzyme solutions for cannabis processing provide an edge. By optimizing extraction processes, these enzymes allow for a more sustainable approach to cultivation. They reduce the need for harsh chemicals and excessive energy use, aligning with eco-friendly growing practices.

Enzymes play a pivotal role in optimizing cannabinoid yield by breaking down plant cell walls, which makes the valuable compounds within more accessible. This leads to a more complete extraction process. For growers, this means they can achieve higher yields with the same amount of plant material, thus maximizing their return on investment.

Furthermore, enzymes help in maintaining the structural integrity of sensitive compounds, ensuring that the cannabinoids are not degraded during the extraction process. This preservation of quality is essential for producing top-tier cannabis products that stand out in a competitive market. The application of enzymes not only boosts yield but also elevates the overall quality of the extracts.

Promos & Deals

Sustainable Enzyme Use in Cannabinoid Processing

Sustainability is more than a buzzword; it’s a necessity in today’s world. Enzymes offer a sustainable solution by minimizing environmental impact. They operate at lower temperatures and pressures, reducing energy consumption and preserving natural resources.

For growers committed to eco-friendly practices, industrial enzymes for cannabinoid processing provide a viable path forward. They allow for efficient extraction while maintaining the integrity of the environment. By integrating these enzymes, the industry can move towards a more sustainable future.

- Lower energy requirements

- Reduced chemical waste

- Enhanced plant utilization

The use of sustainable enzyme solutions is not only beneficial for the environment but also for the economic viability of cannabis operations. By cutting down on energy usage and minimizing waste, producers can significantly reduce operational costs. These savings can then be reinvested into further innovations and improvements in the cultivation process.

Additionally, sustainable enzyme use aligns with consumer demand for environmentally conscious products. As more consumers prioritize sustainability in their purchasing decisions, companies that adopt green practices stand to gain a competitive advantage. Enzymatic processes exemplify a commitment to environmental stewardship while delivering high-quality cannabis products.

Enzyme-Assisted Cannabinoid Production Techniques in Practice

Implementing enzyme-assisted techniques requires knowing the specific needs of different strains. Each strain, like Blue Dream, has unique characteristics that enzymes can enhance. By tailoring enzyme use, growers can achieve optimal results, much like a chef adjusting spices to perfect a dish.

Real-life examples show that enzymes can drastically reduce processing times. This means faster turnaround from plant to product, which is crucial for meeting market demands. Growers can maintain quality while increasing output, ensuring they stay competitive in a rapidly growing industry.

The practical application of enzyme-assisted cannabinoid production techniques can vary greatly depending on the strain and desired outcome. Growers must be adept at selecting the right enzyme formulations and concentrations to match the specific characteristics of the cannabis they are processing. This customization ensures that the enzymatic reactions are optimized to deliver the best results.

Furthermore, the incorporation of these techniques can lead to more innovative product offerings. By refining the extraction process through enzymes, producers can explore new product lines with unique cannabinoid profiles and enhanced flavors. This diversification not only meets consumer demand but also strengthens market positioning.

FAQs

What are industrial enzymes for cannabinoid processing?

Industrial enzymes for cannabinoid processing are biological catalysts that enhance the extraction of cannabinoids from cannabis plants. They work by breaking down plant materials, making it easier to isolate and extract valuable compounds like THC and CBD. This process improves the overall efficiency of cannabinoid production, resulting in higher yields and purer products.

Using enzymes can significantly reduce the need for harsh chemical solvents, making the process more environmentally friendly. For those new to cannabis cultivation, incorporating enzymes can simplify the extraction process, offering a more sustainable and efficient method of producing cannabis extracts.

These enzymes are designed to target specific components of the plant structure, ensuring that the extraction process is not only thorough but also gentle on the cannabinoids themselves. This precision is vital for preserving the quality and potency of the final product, which is crucial for both medical and recreational cannabis applications.

Moreover, industrial enzymes for cannabinoid processing are continually evolving, with research and development yielding more effective formulations. This evolution means that the benefits of enzymatic processing continue to grow, offering producers new opportunities to enhance their operations and meet the changing demands of the cannabis market.

How do enzymes improve cannabinoid extraction efficiency?

Enzymes improve cannabinoid extraction efficiency by breaking down complex plant structures, allowing for easier access to cannabinoids. This means that more cannabinoids can be extracted from the same amount of plant material, increasing overall yield. It’s like having a more precise tool that can extract every last bit of valuable compound from the plant.

This increased efficiency can result in significant cost savings and higher-quality products. For growers, this means getting more from each harvest, maximizing the potential of every plant. Enzymes offer a way to enhance efficiency without compromising on quality.

By facilitating a more complete extraction, enzymes also help in minimizing the presence of unwanted by-products or impurities in the final extract. This leads to a cleaner, more potent product that meets the high standards of modern cannabis consumers. The enhanced purity achieved through enzymatic extraction is a significant selling point for premium cannabis products.

Furthermore, the use of enzymes allows for a more controlled extraction process, reducing the variability that can occur with traditional methods. This consistency is essential for producers who need to ensure that each batch of product meets rigorous quality standards. With enzymes, the extraction process becomes more predictable and efficient, leading to better outcomes overall.

Can enzymes be used with all cannabis strains?

Yes, enzymes can be used with a wide variety of cannabis strains, but the specific enzyme solution and method may vary based on the strain’s characteristics. Some strains may respond better to certain enzyme formulations, so it’s important to understand the unique needs of each strain.

For instance, a strain like GG4 might require a different enzyme approach than OG Kush. By tailoring the enzyme use to the strain, growers can optimize both yield and quality, ensuring the best possible outcome.

Knowing the genetic makeup and specific attributes of each strain is crucial for selecting the right enzymatic approach. This customization allows growers to harness the full potential of each strain, whether they are aiming for high THC content, specific terpene profiles, or other desirable traits.

Additionally, as new strains are developed, the flexibility of enzyme-assisted techniques offers an adaptable solution that can be modified to fit emerging needs. This adaptability is particularly valuable in an industry that is constantly evolving, enabling producers to stay ahead of trends and consumer preferences.

What are the benefits of sustainable enzyme use in cannabis processing?

Sustainable enzyme use in cannabis processing offers numerous benefits, including reduced environmental impact and improved resource efficiency. Enzymes function effectively at lower temperatures and pressures, which means they require less energy, contributing to a smaller carbon footprint.

Additionally, enzymes can minimize chemical waste, as they often reduce or eliminate the need for harsh solvents. This not only benefits the environment but also creates a safer working environment for those involved in the extraction process. Overall, sustainable enzyme use aligns with eco-friendly growing practices while enhancing product quality.

Furthermore, the reduced reliance on chemical solvents makes the extraction process safer for both workers and consumers. By minimizing potential exposure to harmful substances, enzymes contribute to a healthier production environment and a safer final product.

Finally, the use of sustainable practices, such as enzyme-assisted extraction, can enhance a company’s brand image, appealing to environmentally conscious consumers. This reputation for sustainability can open doors to new markets and foster customer loyalty, providing a competitive edge in the growing cannabis industry.

Are there any challenges with using industrial enzymes in cannabinoid processing?

While industrial enzymes for cannabinoid processing offer many advantages, there are challenges to consider. One potential issue is the initial cost of enzyme solutions, which can be higher than traditional methods. However, the long-term benefits, such as increased yield and reduced waste, often outweigh these initial costs.

Another challenge is the need for proper knowing and application of enzyme technology. Growers must be educated on how to effectively integrate enzymes into their processes to fully realize their benefits. With the right knowledge and application, these challenges can be overcome, leading to a more efficient and sustainable production process.

There may also be a learning curve associated with implementing new enzymatic processes, which requires training and adaptation from staff. Ensuring that the workforce is skilled in these techniques is essential for maximizing the benefits and minimizing potential disruptions during the transition period.

Despite these challenges, the long-term advantages of adopting enzyme-assisted techniques, such as improved efficiency and sustainability, make them a worthwhile investment. As the industry continues to grow, the ability to adapt and innovate with technologies like enzymes will be crucial for maintaining competitiveness and driving success.